What Makes CBF's Brock Environmental Center One of the Most Environmentally Smart Buildings in the World?

The Chesapeake Bay Foundation's vision for the Brock Environmental Center was to again create a cutting-edge facility, as we did in 2000 by building the first LEED Platinum building in the world.

The Brock Center exists in concert with its natural surroundings, with minimal impact on the surrounding land, air, creeks, river, and Chesapeake Bay. Every aspect of the center—its location, materials, construction, utilities, operation, and use—meets the strictest environmental standards, resulting in the least impact possible.

CBF's goal for the center is to raise the bar for environmentally intelligent building and living. The center is LEED-Platinum certified and achieved Living Building Challenge certification, a specific and highly exceptional designation from the International Living Future Institute. This rare designation means the building has a "net zero" impact on the environment, not just when construction is completed but after the center has been operating for a year with proven performance. As a Living Building, the center is a national and international model for green building techniques, materials, energy efficiency, water use, and landscaping as well as efficiency, beauty, and inspiration—a facility the entire region can visit, use, enjoy, and take pride in.

Brock Center architects SmithGroupJJR is a national leader in sustainable buildings. In this video, co-leaders Russell Perry, Greg Mella, and Don Posson talk about some of the most significant trends in sustainable design. Trends which have been incorporated into the Brock Center. Go to our Multimedia page to view larger.

Achieving Energy Independence

CBF's Brock Environmental Center uses only as much energy as it generates over the course of a year. It employs aggressive energy conservation techniques such as highly efficient geo-thermal heating and cooling, natural day lighting, dynamic natural ventilation systems and design, and weather-dependent window opening patterns. The building uses photo-voltaic solar roof panels and two small wind turbines to generate energy.

-

Natural Ventilation

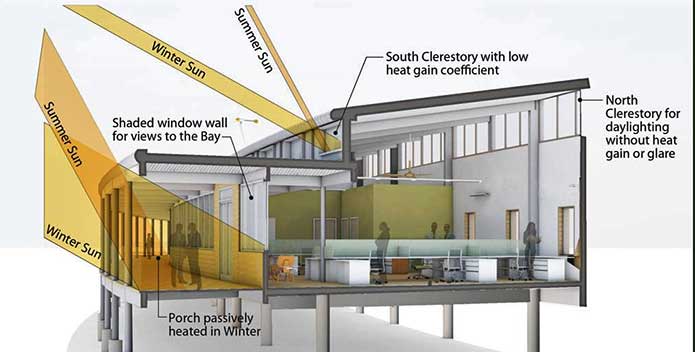

To reduce the need for electricity, the building is situated to receive maximum southern exposure for warmth and to take advantage of prevailing winds for natural ventilation. Using the sun's heat in the winter and natural ventilation during warm months, the heating and cooling systems are not needed approximately 15 percent of the year. Image courtesy Smith Group JJR

-

Daylighting and Sunshading

Natural daylight from the northern window wall illuminates the entire building without glare, substantially reducing what is usually an office's most significant energy cost, electric lighting. Ideally, overhead overhead lights won't be needed during the day. Also, an open office layout allows daylight to be distributed throughout the building, providing more efficient heating and cooling. Roof and eaves are designed to provide shade in the summer, to prevent glare, and help further reduce cooling costs. Image courtesy Smith Group JJR

-

Geothermal Wells

The center's design takes advantage of the earth's constant temperature (about 54° in this region) to provide heating and cooling. Under the fire lane on the north side of the center, geothermal wells create a loop 300 feet below ground. Liquid circulates through the loop, extracting cool temperatures from the ground in the summer and warm temperatures in the winter. A high efficiency HVAC system is used to distribute air at a moderate, comfortable temperature throughout the building. Image courtesy Northern Weathermakers

-

Super Insulation

Exterior walls, floors, and roof insulation are designed to reduce energy demands by maximizing the building's insulation envelope, achieving the most efficient "R value" for the building's use. Energy modeling indicates that the center's most efficient R value will be R50 for the roof, R35 for the walls, and R31 for the floor (because the building is raised). By comparison, R values in insulation for most new buildings typically are R10 to R15. Image courtesy Model Group

-

Solar Power

Rooftop photo-voltaic panels produce approximately 60 percent of the Brock Environmental Center's energy needs by converting the sun's energy to electricity. Photo courtesy Conserve Energy

-

Wind Turbines

Two small 10-kilowatt wind turbines provide approximately 40 percent of the Brock Environmental Center's energy by converting wind energy to electricity. Photo courtesy Planet Save

Achieving Water Independence

The Brock Environmental Center is designed to capture, store, and filter all of its water needs. The center treats and reuses rain water for drinking, hand-washing, showering, cleaning, and irrigation. No-flush Clivus composting toilets are used. Gray water (wastewater generated from sinks and showers) is cleansed with a constructed wetland technique. Excess rain water is filtered slowly through a rain garden. Rain Water captured from rooftops is stored in cisterns and used for drinking water, hand-washing, cleaning, irrigation, and other general uses.

-

Rain Water

Water captured from rooftops is filtered and stored in cisterns and used for drinking water, hand-washing, cleaning, irrigation, and other general uses. Image courtesy Smith Group JJR

-

Rain Gardens

Excess rain water is treated and routed to rain gardens where it sinks into the soil and is naturally filtered. This keeps the excess rain water from picking up pollutants and running off into Pleasure House Creek, Crab Creek, the Lynnhaven River, or the Chesapeake Bay. Photo courtesy Stormwater Management

-

Composting Toilets

Composting toilets use no water at all. Human waste is composted naturally over time to produce a sanitary soil enhancer (compost) for the site's native landscaping. This saves water and reduces the load on sewage treatment plants that contribute nutrient pollution to our waterways. Liquid waste is sent to a Hampton Roads Sanitation District fertilizer production facility. Image courtesy Smith Group JJR

-

Constructed Wetlands

All gray water (wastewater generated from sinks and showers) is treated through constructed wetlands through a process called biofiltration. Gray water is channeled through a wetland constructed of native plants where natural processes clean it and return it to the underground aquifer. Photo courtesy Technorati

Materials

-

Recycled and Renewable Materials

Businesses and organizations in Hampton Roads have donated salvaged building materials for various construction components. From mop sinks to wood doors to old bleachers (for door trim—see left) were reused and repurposed to construct the Brock Environmental Center. See our list of salvaged materials. Photos by CBF Staff

-

Red List Materials

To meet the Living Building Challenge™, designers must do more than simply meet net-zero energy and water use requirements. They also must do so without using any materials on the "Red List," which includes chemicals and materials considered harmful to humans and the environment. Materials and chemicals listed on the Living Building Challenge's™ Red List include polyvinyl chloride (PVC), chemically treated wood, and halogenated flame retardants, among others.

See how we're doing by checking the Brock Environmental Center Materials Tracking Spreadsheet.

Image courtesy Sustainable Business

Place

-

Preventing Site Disturbance

The site's design and construction are predicated on minimal disturbance to the land and water. Automobile parking for visitors and staff is available in designated parking areas or on city streets. The center is sited 200 feet beyond the water's edge—100 feet above and beyond Virginia's standard 100-foot Chesapeake Bay Preservation Act Resource Protection Area. Photo courtesy Smith Group JJR

-

From Dredge Spoil to a Native Landscape

The property had been modified over the years by the placement of millions of cubic yards of dredge spoil from nearby waterways. CBF will restore habitat for local and migratory wildlife by planting native trees, shrubs, and grasses; protecting and restoring wetlands; and conducting oyster restoration activities. Image Google Earth

-

Polluted Runoff

The Brock Environmental Center is a model for effective, site-based stormwater management, a practical example of the Chesapeake Clean Water Blueprint in action. It prevents increases in peak runoff volume and net increases in runoff volume and pollutants. Permeable roads and paths allow water to filter into the soil, while rain garden treatment, rain water harvesting, and water re-use reduce the volume of runoff and meet pollution-reduction objectives. The site design ensures that all runoff on CBF's property is filtered through the vegetation and the soil, not flowing untreated into local waters. Photo © Krista Schlyer/iLCP

Preparation for Major Storms, Flooding, and Sea-Level Rise

The Brock Environmental Center sits on pylons, which allow any flood water entering the site to remain onsite and either sink into the soil or recede without impacting the building's structure. The building's first floor elevation is 13.8 feet above sea level to exceed the standard for a 500 year storm event and future sea level rise projected flooding.

CBF's Brock Environmental Center raises the bar and is a model of environmentally smart building, energy and water efficiency, and climate change resilience that we hope engages, informs, and inspires the region to solve the Bay's challenges in innovative and collaborative ways.